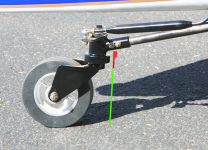

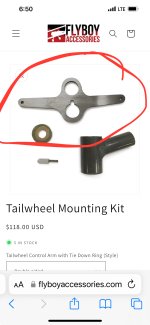

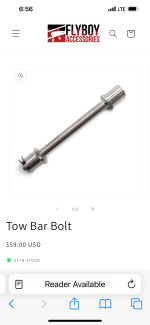

I have the stock tailwheel, with the forward pin (or whatever it’s actually called — the vertical swivel part) very close to the ground. I’m interested in getting one of the aftermarket forks that angle down, lifting the pin a little higher. Also considering a pneumatic tailwheel, as I have a long taxi.

The questions:

1) Which aftermarket forks are generally considered the best? I don’t want to exchange a fork that‘s too low for one that shimmies.

2) Will a new fork lift the tail enough to alter takeoff and landing?

The questions:

1) Which aftermarket forks are generally considered the best? I don’t want to exchange a fork that‘s too low for one that shimmies.

2) Will a new fork lift the tail enough to alter takeoff and landing?