Draker

Well Known Member

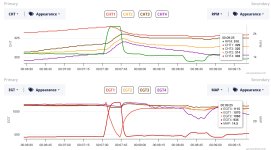

I recently replaced and re-routed some fuel lines under the cowl to keep them away from heat sources. As usual, I performed a post-maintenance flight test to verify my work. Did my usual (50% power) runup with no issues, lined up and went full power. During my usual takeoff run scan, I noticed I was only making 2300 RPM (expected 2700) and then checked my EGT/CHT gauges. Cylinder 1's EGT was about half what it should have been and falling, and the CHT was falling rather than rising. (see attached plot) I was still on the ground so I made the easy decision to cut power and apply brakes.

I couldn't think of anything that I had significantly changed. Just two hose lengths, and now they are away from heat sources so it should run better. My only theory was that in the process of changing out the hoses, I had to also remove the red cube which is mounted on top of the engine, connected to the fuel spider. It's possible that during that process some small amount of dirt, dust, or other contaminant got into the spider and made its way to the #1 injector. I'm at 80 hours on the engine, and have never cleaned the injector nozzles, so I thought I'd give it a try.

Following Lycoming SI 1275C, I removed the injector nozzles to inspect them. The insides were a little brown but didn't seem particularly dirty, and I did not discover a "smoking gun" piece of dirt. However: there is a little screen embedded in each of the nozzles, and those screens were absolutely filthy. I did not need a magnifying glass--I could see visible gunk in them! So I gave them each a 30 minute bath in Hoppe's #9, and then gently scrubbed away the gunk with a soft toothbrush. I don't have an ultrasonic cleaning vat unfortunately. I wish I got a picture of the gunk, it was pretty grody.

Re-installed the injectors, torqued them per Lycoming's doc, and did a test flight. Everything is running fine now, subjectively I'd say better than ever:

1. the EGTs seem to "peak" closer together, and I feel (have not analyzed the data, but will soon) that I can lean a bit more aggressively than I could in the past before roughness sets in.

2. I can now idle on the ground smoothly at 550RPM, whereas before, I started getting roughness around ~600RPM.

Not sure if either of these effects can be attributed to cleaner injectors, but if not, I'd love to hear theories. I'm also a bit concerned about how my (basically new, 80 hour) injector screens bacame so cruddy. Could this have just been post-filter contamination from the initial build?

I couldn't think of anything that I had significantly changed. Just two hose lengths, and now they are away from heat sources so it should run better. My only theory was that in the process of changing out the hoses, I had to also remove the red cube which is mounted on top of the engine, connected to the fuel spider. It's possible that during that process some small amount of dirt, dust, or other contaminant got into the spider and made its way to the #1 injector. I'm at 80 hours on the engine, and have never cleaned the injector nozzles, so I thought I'd give it a try.

Following Lycoming SI 1275C, I removed the injector nozzles to inspect them. The insides were a little brown but didn't seem particularly dirty, and I did not discover a "smoking gun" piece of dirt. However: there is a little screen embedded in each of the nozzles, and those screens were absolutely filthy. I did not need a magnifying glass--I could see visible gunk in them! So I gave them each a 30 minute bath in Hoppe's #9, and then gently scrubbed away the gunk with a soft toothbrush. I don't have an ultrasonic cleaning vat unfortunately. I wish I got a picture of the gunk, it was pretty grody.

Re-installed the injectors, torqued them per Lycoming's doc, and did a test flight. Everything is running fine now, subjectively I'd say better than ever:

1. the EGTs seem to "peak" closer together, and I feel (have not analyzed the data, but will soon) that I can lean a bit more aggressively than I could in the past before roughness sets in.

2. I can now idle on the ground smoothly at 550RPM, whereas before, I started getting roughness around ~600RPM.

Not sure if either of these effects can be attributed to cleaner injectors, but if not, I'd love to hear theories. I'm also a bit concerned about how my (basically new, 80 hour) injector screens bacame so cruddy. Could this have just been post-filter contamination from the initial build?