I replaced Vans old style flap actuator with the upgraded actuator that has built in position sensor. I have a VP-X system for flap control and the new actuator position sensor is not working properly; the position changes full scale with only minimal change in flap position. Has anyone else had this problem? Solution?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problem upgrading flap actuator

- Thread starter bob888

- Start date

Would seem the range is different between the two position sensors. I’m not familiar with the VPX, but does the resistance range of the wiper sensor need to be programmed? If the old sensor has a range of 0-500 Ohms and the new one has a range of 0-5000 Ohms, then the VPX thinks full range is only 500 Ohms, thus moving only 10%.

Radomir

Well Known Member

The range of raw position reading is different. You will have to reprogram... start by hooking up the computer to VPX and read raw values for full up and full down (and any stops in between). Program that.. I also did this upgrade and had no issues, but did note that raw readings were completely different and it would not have worked well without reprogramming.

Same here. Works perfectly on my RV10 when you configure the VPX to accept the new position readings from the Vans Flap motor.

Vertical Power has a software tool called ‘VP-X Configurator’ that walks you through the process once you connect a PC to the VPX unit as Radomir mentioned.

Vertical Power has a software tool called ‘VP-X Configurator’ that walks you through the process once you connect a PC to the VPX unit as Radomir mentioned.

I have done the reprogramming but the VP-X configurtaor still runs from 0 to 225 within the first 5% of travel. The documentation for the actuator says it has a Hall effect position sensor but the schematic just shows a potentiometer circuit. That schematic calls for 5 volts input but I discovered the VP-X is only providing 2.5 volts. Maybe I have the wrong or a defective unit. My model is Progressive Automations PA-09-450-POT. Any further suggestions will be appreciated.

I was also worried about the stated differences of 5V vs 2.5V so I called Vertical Power and they thought it should work and it did for my install. I’m not near my plane at the moment but I vaguely guess that my min and max settings on the VPX is something like 45 to 220.

To find them I recall an option to remove the position limits in the Confiurator. I then had the flap motor move its full range to see what the min & max readings are. It could be that you need to have the VPX move the flaps the full range before it gives accurate position readings.

I had to configure the min & max values to stop the flaps a couple digits closer to the middle so that those values determined when the flaps would stop rather than when the flaps hit their hard position stops and the flap motor would stop on it’s own. Otherwise the VPX might continue to send voltage to the flap motor (if the flap motor stops on its own first) and then disable the circuit after a number of seconds thinking something is wrong (this time is adjustable).

You can then also program in the intermediate stops that you have. I set my stops at 10deg, 20deg, and full flaps.

To find them I recall an option to remove the position limits in the Confiurator. I then had the flap motor move its full range to see what the min & max readings are. It could be that you need to have the VPX move the flaps the full range before it gives accurate position readings.

I had to configure the min & max values to stop the flaps a couple digits closer to the middle so that those values determined when the flaps would stop rather than when the flaps hit their hard position stops and the flap motor would stop on it’s own. Otherwise the VPX might continue to send voltage to the flap motor (if the flap motor stops on its own first) and then disable the circuit after a number of seconds thinking something is wrong (this time is adjustable).

You can then also program in the intermediate stops that you have. I set my stops at 10deg, 20deg, and full flaps.

Radomir

Well Known Member

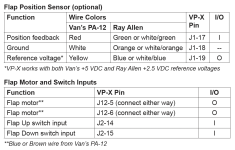

The wiring is the same.. Take a look here on page 4: https://www.vansaircraft.com/wp-content/uploads/2022/10/OP-64-RV-10-Flap-motor-retrofit.pdfThanks for your help guys. I note that you gave info for Vans PA12. I have a PA09, also from Vans. I wonder if that is the problem.

Looking at the different actuator models on the Progressive Automations website I can confirm that I‘m also using the PA-09 model. https://www.progressiveautomations.com/products/mini-medium-force-linear-actuator