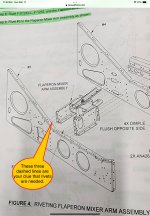

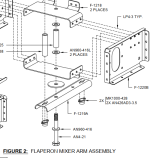

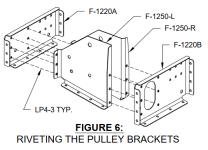

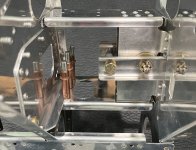

I finished Section 21 a while ago, but I noticed these three holes not riveted. I looked at 21 page 8, which is where the flapperon mixer box gets attached to #3 seat rib. Looks like I didn't take the LP4-3 TYP note liberally enough, or do these get riveted elsewhere. It's not explicitly called put in the drawing and there are no visual call outs.

Everyone else have this riveted?

Everyone else have this riveted?