Not sure why the WD-807 becomes stiff as soon as I tighten the last bolt to rod end bearing. Nothing appears to bind. The bearing housing is centered in the brackets. If I loosen the bolt the WD-807 swings freely. After 1/4 turn of the wrench it becomes stiff. Wondering if there should be some stiffness to WD-807 or should it swing freely after torquing top bolt.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WD-807 becomes stiff when attaching front bolt. RV-8

- Thread starter HackDog

- Start date

It should swing very freely with all attaching bolts torqued. However, mine had the same problem you are seeing.

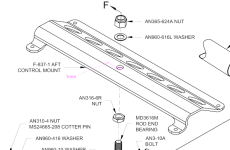

Turned out there were two problems. First, the rod ends were rotating slightly as the AN365-624A lock nuts were torqued. The rod ends therefore tended to jam against their supporting lugs on the WD-807 control column weldment. Was able to fix this by using an aluminium wedge to hold the rod end faces parallel to the weldment lug faces while torquing.

Second, more important, problem was the longitudinal distance between the rod end mounting holes in F-849 forward control mount and F-837-1 aft control mount. With the F-837-1 aft control mount temporarily installed by AN3 bolts in all four attaching holes, the distance between mounting holes was about 1mm less than the distance between the rod end bearings as measured on WD-807 control column. Noting that Van's says the aft control mount is not a major structural element, and has allowed previous builders to slot holes in it, I extended the ⅜" hole about 1mm aft, then reinstalled and retorqued the aft rod end bearing. No more problems, very smooth and easy lateral movement of control column.

Hope this helps

Turned out there were two problems. First, the rod ends were rotating slightly as the AN365-624A lock nuts were torqued. The rod ends therefore tended to jam against their supporting lugs on the WD-807 control column weldment. Was able to fix this by using an aluminium wedge to hold the rod end faces parallel to the weldment lug faces while torquing.

Second, more important, problem was the longitudinal distance between the rod end mounting holes in F-849 forward control mount and F-837-1 aft control mount. With the F-837-1 aft control mount temporarily installed by AN3 bolts in all four attaching holes, the distance between mounting holes was about 1mm less than the distance between the rod end bearings as measured on WD-807 control column. Noting that Van's says the aft control mount is not a major structural element, and has allowed previous builders to slot holes in it, I extended the ⅜" hole about 1mm aft, then reinstalled and retorqued the aft rod end bearing. No more problems, very smooth and easy lateral movement of control column.

Hope this helps

Any side load in the ball of a rod end will induce rotational friction. The more the side load, the higher the friction.Not sure why the WD-807 becomes stiff as soon as I tighten the last bolt to rod end bearing. Nothing appears to bind. The bearing housing is centered in the brackets. If I loosen the bolt the WD-807 swings freely. After 1/4 turn of the wrench it becomes stiff. Wondering if there should be some stiffness to WD-807 or should it swing freely after torquing top bolt.

When the bolt is fully loosened, inspect fo any gap between the rod end and the front or back leg of the control column, were you can add a shim.

Yep, that was exactly it. It was about 3/8 of an inch. I just took a Dremel to it and it loosened right up. Thank you so much for that. I really appreciate it.It should swing very freely with all attaching bolts torqued. However, mine had the same problem you are seeing.

Turned out there were two problems. First, the rod ends were rotating slightly as the AN365-624A lock nuts were torqued. The rod ends therefore tended to jam against their supporting lugs on the WD-807 control column weldment. Was able to fix this by using an aluminium wedge to hold the rod end faces parallel to the weldment lug faces while torquing.

Second, more important, problem was the longitudinal distance between the rod end mounting holes in F-849 forward control mount and F-837-1 aft control mount. With the F-837-1 aft control mount temporarily installed by AN3 bolts in all four attaching holes, the distance between mounting holes was about 1mm less than the distance between the rod end bearings as measured on WD-807 control column. Noting that Van's says the aft control mount is not a major structural element, and has allowed previous builders to slot holes in it, I extended the ⅜" hole about 1mm aft, then reinstalled and retorqued the aft rod end bearing. No more problems, very smooth and easy lateral movement of control column.

Hope this helps

JonJay

Well Known Member

3/8” where? Dremel’d what?Yep, that was exactly it. It was about 3/8 of an inch. I just took a Dremel to it and it loosened right up. Thank you so much for that. I really appreciate it.

That’s kind of the opposite of adding shims.

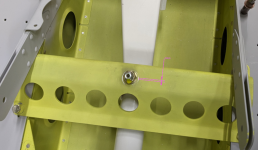

Not sure about the OP, but I just slightly extended the centre hole in the aft control mount, as sketched below.3/8” where? Dremel’d what?

That’s kind of the opposite of adding shims.

If you look closely, you can probably tell from the socket marks on the primer just how much I needed to move it.

I did look at shimming the rod end bearings, but there's not a whole lot of freeplay between the ears of the clevis-type weldments.

Note this wasn't an unknown problem or solution - see for example Jeff Preou's build log

In instances where the cause of the issue isn’t from a gap at the clevis at the fwd. end of the control column, but the overall spacing between the fwd. and aft rod ends needs to be bigger, it is also acceptable install a shim spacer behind the front angle bracket to move it fwd.