Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What all is needed to swap bottom pivot rudder pedals to the top pivot ones?

- Thread starter Oroyo

- Start date

The early RV-6(A) had floor mount rudder pedals and the later versions use the overhead rudder pedals like in the RV-7(A) and RV-9(A).

One will need to look at the plans for the overhead rudder pedals to figure out everything that is needed. I am not sure if the old steel welded brake pedals will work with the newer style overhead rudder pedals.

I have the older style floor mounted rudder pedals and like it but agree that the overhead would give the PAX more leg room. I would think all the parts that are on the revised drawing are needed to convert to the overhead rudder pedals. My best guess is only the master cylinders and fittings will be reusable. Some of the bolts may be able to be reuse but in the total cost of the project, I would use all new hardware.

At my age, the hardest part of converting to overhead rudder pedals would be working under the panel. At may age and fatness, it is difficult to get in / out and work in that location.

One will need to look at the plans for the overhead rudder pedals to figure out everything that is needed. I am not sure if the old steel welded brake pedals will work with the newer style overhead rudder pedals.

I have the older style floor mounted rudder pedals and like it but agree that the overhead would give the PAX more leg room. I would think all the parts that are on the revised drawing are needed to convert to the overhead rudder pedals. My best guess is only the master cylinders and fittings will be reusable. Some of the bolts may be able to be reuse but in the total cost of the project, I would use all new hardware.

At my age, the hardest part of converting to overhead rudder pedals would be working under the panel. At may age and fatness, it is difficult to get in / out and work in that location.

blaplante

Well Known Member

The overhead pedal weldments run full width of the cockpit. Look at the plans, or someone else's plane to see. Cut a 1" wood dowel rod to that length. See if you can actually get it wrestled in before you go buy parts. It was difficult with no panel in the plane. In a completed plane with panel wiring, and control cables, it could be a real pain.

Besides the brake pedal issue (and maybe the brake cylinders, I don't know), you need a center brace, and the 3 sets of nylon blocks that the pedals mount into. And the AN hardware that mounts the pedals. Plus the links which connect the rudder cables to the pedal weldments.

Besides the brake pedal issue (and maybe the brake cylinders, I don't know), you need a center brace, and the 3 sets of nylon blocks that the pedals mount into. And the AN hardware that mounts the pedals. Plus the links which connect the rudder cables to the pedal weldments.

Having removed and re-installed the overhead pedals to apply the service bulletin, I can confirm that it's difficult, but not impossible, to install them on a completed plane. It's just an exercise in geometry, working the weldments into place carefully and in the right order to get them around existing cables etc. You (or someone) will be upside down under the panel, so be sure you're up to it in terms of flexibility and mobility.

Scott Hersha

Well Known Member

Vans has a kit Just for this purpose. It comes with everything you need. Check out the ‘kit contents’ to see what comes with it. It’s a big job, but you said you are “flexible”, so maybe not too tough for you - except maybe the cost….

Sam Buchanan

been here awhile

I’m looking for maximum leg room. I see the pedal weldments are sold each left and right but what else if anything?

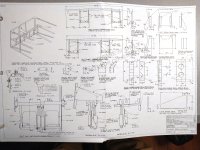

You are going to need pretty much everything on drawing 43A.

Attachments

Cool thanks! I thought I’d seen a kit but couldn’t find it in my search this morning.Vans has a kit Just for this purpose. It comes with everything you need. Check out the ‘kit contents’ to see what comes with it. It’s a big job, but you said you are “flexible”, so maybe not too tough for you - except maybe the cost….

Desert Rat

Well Known Member

Does your 6 have a recessed box in the firewall like the 7? If so, I think the biggest hassle of this operation is going to be riveting the center brace to the vertical firewall angle because the recess box is in the way. I don't know that you even have enough room to seat pull rivets in there without getting creative. The second biggest hassle will be match drilling the outside bearing blocks to the short fwd fuselage longerons because you have to match drill them from above.

Nothing that cant be done, but yeah, a trained monkey would be a good investment.

Nothing that cant be done, but yeah, a trained monkey would be a good investment.

blaplante

Well Known Member

I *think* the recessed box came later.Does your 6 have a recessed box in the firewall like the 7? If so, I think the biggest hassle of this operation is going to be riveting the center brace to the vertical firewall angle because the recess box is in the way. I don't know that you even have enough room to seat pull rivets in there without getting creative. The second biggest hassle will be match drilling the outside bearing blocks to the short fwd fuselage longerons because you have to match drill them from above.

Nothing that cant be done, but yeah, a trained monkey would be a good investment.

A 90 degree air drill like https://www.ebay.com/itm/235455655679 is one of the best things I ever bought. and is the first thing I'd reach for for drilling those outside bearing blocks to the short longerons.

Does your 6 have a recessed box in the firewall like the 7? If so, I think the biggest hassle of this operation is going to be riveting the center brace to the vertical firewall angle because the recess box is in the way. I don't know that you even have enough room to seat pull rivets in there without getting creative. The second biggest hassle will be match drilling the outside bearing blocks to the short fwd fuselage longerons because you have to match drill them from above.

Nothing that cant be done, but yeah, a trained monkey would be a good investment.

The recess was an option when I built my -6. (1st flight 1997)I *think* the recessed box came later.

A 90 degree air drill like https://www.ebay.com/itm/235455655679 is one of the best things I ever bought. and is the first thing I'd reach for for drilling those outside bearing blocks to the short longerons.

The angle air drill can be helpful but an angle flex shaft drill attachment may be better to get at some of the hard to get places.

Larco

Well Known Member

Most of the earlier builders like Gary know of this problem. But I have had some friends run into this. If the fresh air inlets on the side of the plane are mounted too low above the longeron there will not be enough room between the vent and the longeron for the overhead pedal mount brackets.The recess was an option when I built my -6. (1st flight 1997)

The angle air drill can be helpful but an angle flex shaft drill attachment may be better to get at some of the hard to get places.

Some builders with floor mounted pedals installed the vents without any guidance, there wasn't any that I know of, and got them too close to the longeron. Of course who knew that there would be an overhead option later on?

Just something to check out before you make plunge?

Oh boy this is getting interesting now. I can already feel the contortion pains lol. Sounds like it’s going to be a real pickle to get this done, but I kinda like weird projects like this. It will be worth it for me as I’m too damn tall. I’d order the kit today but with all the recent grumbling about price changes and uncertain ship times I’m a bit hesitant being that the kit is back ordered. do we think it will ever get back in stock or is this a kit they only make as needed when back orders arrive?

Last edited:

Dad's RV-10

Well Known Member

I’d order the kit today but... ...I’m a bit hesitant being that the kit is back ordered

"Kit" part numbers are frequently listed as backordered, which is often misleading. The kit consists of multiple individual parts which have to be individually picked and "assembled" into the kit.

Because these parts are often not already sitting on a shelf, in one bin, already picked and "assembled" as the kit part number, they often show in the store as back ordered.

The majority of the time, all of the individual kit parts are available. Once you place your order, the individual parts are picked off the shelves and your order will be processed without delay.

Sam Buchanan

been here awhile

Oh boy this is getting interesting now. I can already feel the contortion pains lol. Sounds like it’s going to be a real pickle to get this done, but I kinda like weird projects like this. It will be worth it for me as I’m too damn tall. I’d order the kit today but with all the recent grumbling about price changes and uncertain ship times I’m a bit hesitant being that the kit is back ordered. do we think it will ever get back in stock or is this a kit they only make as needed when back orders arrive?

As you contemplate this mod here is a tip that will make installation of the overhead pedals easier. I ran into this when I removed the overhead pedals in my RV-6 many years ago for the gusset service bulletin.

You can split the nylon bearing blocks that install on the fuse longerons. Otherwise they are an extremely tight fit or may even be impossible to wedge into position since each RV-6 fuse can have minute dimensional variations. Split the blocks horizontally and insert a washer or shim between them to account for the saw kerf when they are split and this will maintain the proper bearing clearances on the pedal support tube . This makes the blocks immensely easier to install when assembling the pedals.

I would make a drill guide/template for drilling the longerons and blocks separately instead of trying to match drill longerons through the blocks. A phone call to Vans will probably clear up any questions about availability of the components needed for the mod. This upgrade can be kinda tedious but very doable if you are patient and determined.

Scott Hersha

Well Known Member

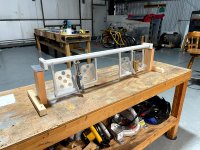

Once you get the dimensions figured out properly, and splitting the blocks as Sam recommends will make it easier, consider building a simple jig for your workbench for putting it all together to lessen the upside down under the panel time. I was able to carefully install mine in my RV6 in one piece almost. Still had to crawl in for the bolts, center support, and hydraulic lines.

Attachments

[email protected]

Well Known Member

OP asked what is necessary.

Lets see:::: the desire to be contorted for quite awhile

Need to build a platform to lay on, foam board and 1/4' plywood

Appointments with Chiropractor if so inclined

If the vent are in the way as they were with mine. cut/slice them off the sidewall. Hopefully they were installed with Proseal.

The first vents I put in were riveted in, cause the plans said to.

It can be done. Stick with it

It gives you a place to put them things called "feet"

Splitting the blocks is mandatory

My luck varies Fixit

Lets see:::: the desire to be contorted for quite awhile

Need to build a platform to lay on, foam board and 1/4' plywood

Appointments with Chiropractor if so inclined

If the vent are in the way as they were with mine. cut/slice them off the sidewall. Hopefully they were installed with Proseal.

The first vents I put in were riveted in, cause the plans said to.

It can be done. Stick with it

It gives you a place to put them things called "feet"

Splitting the blocks is mandatory

My luck varies Fixit

This assumes I have that much free space on a work bench, which is a bit of a tall assumption.Once you get the dimensions figured out properly, and splitting the blocks as Sam recommends will make it easier, consider building a simple jig for your workbench for putting it all together to lessen the upside down under the panel time. I was able to carefully install mine in my RV6 in one piece almost. Still had to crawl in for the bolts, center support, and hydraulic lines.

Thanks, this is seeming like more of a task than I was hoping lol. But my size 12‘s are the ones making the decisions not my sciatic nerves unfortunately. Thanks for the intel and encouragement.OP asked what is necessary.

Lets see:::: the desire to be contorted for quite awhile

Need to build a platform to lay on, foam board and 1/4' plywood

Appointments with Chiropractor if so inclined

If the vent are in the way as they were with mine. cut/slice them off the sidewall. Hopefully they were installed with Proseal.

The first vents I put in were riveted in, cause the plans said to.

It can be done. Stick with it

It gives you a place to put them things called "feet"

Splitting the blocks is mandatory

My luck varies Fixit

[email protected]

Well Known Member

Hey I wear 14's but in tennis shoes all the timeThanks, this is seeming like more of a task than I was hoping lol. But my size 12‘s are the ones making the decisions not my sciatic nerves unfortunately. Thanks for the intel and encouragement.

It can be done if you want .

Fixit