PaulvS

Well Known Member

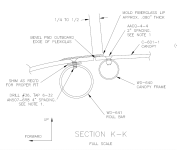

The plans for the sliding canopy show a fiberglass fairing that is molded directly onto the plexi windshield above the roll bar and overlapping the slider edge by 1/4" to 1/2". Obviously the fiberglass needs to bond to the windshield, but NOT to the slider. Normally I use packing tape as a bond breaker, but in this case there is a gap between the windshield and the slider and anything that is put over to bridge the gap while molding will result in the 2 parts being stuck together, forever!

How did you do the molding without gluing the two parts of the canopy together? (other than making a removable fairing and then bonding it on afterwards with Sika etc.)

Thx

Paul.

How did you do the molding without gluing the two parts of the canopy together? (other than making a removable fairing and then bonding it on afterwards with Sika etc.)

Thx

Paul.