Can anyone give me a ballpark value of a mid 60's Cherokee 180 engine (O-360-A3A)? No times known or logbooks. Abandoned uncovered outdoors for at least 5 years. Fuselage a loss due to tornado. I want to make offer gambling on serviceable crankcase. I assume a ton of corrosion on crank and camshaft and non-serviceable heads.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lycoming value

- Thread starter husabeast

- Start date

It is entirely possible that nothing inside is serviceable. $2-3k is probably a fair offer given information you stated. You are gambling and hoping the crankshaft and case are good. Pretty much everything else will need to be replaced.

If it was at TBO and had been flying regularly and believed to be a good engine with no problems, a core usually runs closer to $15k at the moment.

If it was at TBO and had been flying regularly and believed to be a good engine with no problems, a core usually runs closer to $15k at the moment.

I don't want to be a wise a..., are there logs? N number anything on history other then hear say? Wide deck or narrow deck? Outside as in a cowl mounted in the air or just sitting in the dirt. Offer to remove it soak it in oil and take it apart(if you can). Would you risk your life on this engine? I would hope not, fun learning experience offer, scrap metal not Airworthy.Can anyone give me a ballpark value of a mid 60's Cherokee 180 engine (O-360-A3A)? No times known or logbooks. Abandoned uncovered outdoors for at least 5 years. Fuselage a loss due to tornado. I want to make offer gambling on serviceable crankcase. I assume a ton of corrosion on crank and camshaft and non-serviceable heads.

Help me understand aviation engines vs auto/ motorsport a bit better. Can things like cranks rods and cases not be re-conditioned? In the auto world the cases could be surfaced, decked, and line-honed. Rods honed, crank and cam reground (all with limits of course). I would assume the grind limit on an aviation crank to be very minimal, but it has been done to create stroker lycomings.

rocketman1988

Well Known Member

“You bet your life” for 1000, Alex.Help me understand aviation engines vs auto/ motorsport a bit better. Can things like cranks rods and cases not be re-conditioned? In the auto world the cases could be surfaced, decked, and line-honed. Rods honed, crank and cam reground (all with limits of course). I would assume the grind limit on an aviation crank to be very minimal, but it has been done to create stroker lycomings.

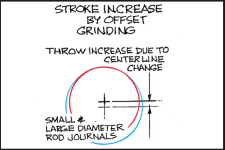

Not following, nothing new for me. How would grinding a journal increase stroke? That doesn't change the geometry of eth crank throw.Help me understand aviation engines vs auto/ motorsport a bit better. Can things like cranks rods and cases not be re-conditioned? In the auto world the cases could be surfaced, decked, and line-honed. Rods honed, crank and cam reground (all with limits of course). I would assume the grind limit on an aviation crank to be very minimal, but it has been done to create stroker lycomings.

Not following, nothing new for me. How would grinding a journal increase stroke? That doesn't change the geometry of eth crank throw.

By offset grinding you change the geometry. The journal diameter is reduced but the throw is increased. Performance Aero did this years ago on a large journal 540. and added 580 cylinders to make a 600.

This is total scrap, If you can get it for free or little value, donated to a tech school for instruction. Lycoming's can be cut three times. .003, .006, .010 Deck height, line boring, welding and moving holes are all part of the rebuild. SKY RANCH Engineering manual will explain it all. A must have to speak Lycoming ( Yes Lycoming is a Language all its own, can sound like Continental or Franklin, but not the same.) The cost of machine work to yellow tag everything is now north of $5K and this is for an old Flat tappet, If you don't understand the Language, get the book start there. IMHO R.Hill

I guess I need to get some lycoming manuals. Every machined component in the world has tolerances. I believe aviation engines are actually fairly loose due to manufacturing capabilities when they were designed. I understand concern with cranks given the gyroscopic and tortional abuse they see swinging a propeller. But cleaning up surface rust and even very minor pitting on rods and even cams should be ok. I'm pretty sure O-200 cams are reground to match the rpm range of formula one engines.“You bet your life” for 1000, Alex.

I was looking for someone knowledgeable to provide some specifics like maybe old metallurgy in these components, or the machine work is cost prohibitive. Or is it just fear and lack of knowledge of options. Perhaps you answered the question.

This would require different connecting rods to maintain the new offset. Sky Ranch Engineering manual , By John Schwaner, 2nd edition $30 on Amazon Everything you will ever need to know. I have the first, I just ordered the 2nd to go with the first, Its that good!View attachment 57642

By offset grinding you change the geometry. The journal diameter is reduced but the throw is increased. Performance Aero did this years ago on a large journal 540. and added 580 cylinders to make a 600.

Last edited:

Thanks! That is what I was looking for.This is total scrap, If you can get it for free or little value, donated to a tech school for instruction. Lycoming's can be cut three times. .003, .006, .010 Deck height, line boring, welding and moving holes are all part of the rebuild. SKY RANCH Engineering manual will explain it all. A must have to speak Lycoming ( Yes Lycoming is a Language all its own, can sound like Continental or Franklin, but not the same.) The cost of machine work to yellow tag everything is now north of $5K and this is for an old Flat tappet, If you don't understand the Language, get the book start there. IMHO R.Hill

Thought you were referring to a standard CS journal grind and oversized bearings. You are truly into customizing here. Not something I'd consider for an "everyday" flyer.View attachment 57642

By offset grinding you change the geometry. The journal diameter is reduced but the throw is increased. Performance Aero did this years ago on a large journal 540. and added 580 cylinders to make a 600.

Journal diameter change is usually addressed by thicker bearings, head clearance/ compression ratio addressed by different pistons. Usually hahaThis would require different connecting rods to maintain the new offset.

Agreed, I was just making the point that reducing the diameter has been done at least on some aviation cranks. So I was curious if a slightly rusty crank could be salvaged the same way. Rhill answered this for me. It sounds like depending on depth of rust it's possible. But likely not economically feesable.Thought you were referring to a standard CS journal grind and oversized bearings. You are truly into customizing here. Not something I'd consider for an "everyday" flyer.

Yes 3,6,10 if you stay on the reservation. There are at least a dozen changes & updates to part numbers over the years also. Most Lycoming parts books can be downloaded online for free, (well paper & ink jet). Keep in mind changes to ignition timing and EI will not work well with some propellers.Journal diameter change is usually addressed by thicker bearings, head clearance/ compression ratio addressed by different pistons. Usually haha