Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flap Actuator Stroke Length?

- Thread starter dmat

- Start date

10 1/4” retracted with a 5” stroke.Does anyone know the stroke length on the vans flap actuator?

Thanks,

D

34-04: Incorrect Flap Motor Length (the value of VAF Forums & the RV Community)

A Build Log detailing the build of a Vans RV-14

I bought the RV-10 flap motor retrofit kit a few months ago (anybody need one? It is for sale) before I realized that it will not work with my panel / harness from SteinAir. Short version of the story - the number and locations of the wires in the harness are different from what is required for the retrofit kit, and I need to just buy a position sensor. The G3x is programmed and ready to go for a sensor, and that's much easier than rebuilding the harness for the retrofit.

SteinAir recommended using the Ray Allen POS-12 with a 1.2 inch stroke measuring length. As far as I can tell (confirmed in the above messages), the Van's flap motor stroke is considerably more than 1.2 inches. I assumed you would just mount the sensor parallel to the piston, but clearly it will run too long for the sensor.

Has anyone added a sensor like this? Where do you mount it and what is it measuring, since I can't just measure the piston position. Thanks!

And, if anyone needs them, I have a few spare parts available for sale.

- RV-10 flap motor retrofit kit

- Van's throttle quadrant

- 3 push pull cables for Van's throttle quadrant

SteinAir recommended using the Ray Allen POS-12 with a 1.2 inch stroke measuring length. As far as I can tell (confirmed in the above messages), the Van's flap motor stroke is considerably more than 1.2 inches. I assumed you would just mount the sensor parallel to the piston, but clearly it will run too long for the sensor.

Has anyone added a sensor like this? Where do you mount it and what is it measuring, since I can't just measure the piston position. Thanks!

And, if anyone needs them, I have a few spare parts available for sale.

- RV-10 flap motor retrofit kit

- Van's throttle quadrant

- 3 push pull cables for Van's throttle quadrant

POS-12 measures resistance, and the avionics control is translating the numerical value into a proxy representation in degrees to display on a panel. You may need to understand this issue in more detail before trying to swap parts. Good luck. It’s similar to the fuel level being translated to gals for the display.I bought the RV-10 flap motor retrofit kit a few months ago (anybody need one? It is for sale) before I realized that it will not work with my panel / harness from SteinAir. Short version of the story - the number and locations of the wires in the harness are different from what is required for the retrofit kit, and I need to just buy a position sensor. The G3x is programmed and ready to go for a sensor, and that's much easier than rebuilding the harness for the retrofit.

SteinAir recommended using the Ray Allen POS-12 with a 1.2 inch stroke measuring length. As far as I can tell (confirmed in the above messages), the Van's flap motor stroke is considerably more than 1.2 inches. I assumed you would just mount the sensor parallel to the piston, but clearly it will run too long for the sensor.

Has anyone added a sensor like this? Where do you mount it and what is it measuring, since I can't just measure the piston position. Thanks!

And, if anyone needs them, I have a few spare parts available for sale.

- RV-10 flap motor retrofit kit

- Van's throttle quadrant

- 3 push pull cables for Van's throttle quadrant

Thanks - my harness has two sets of wires - one for control, one for a position sensor. That's why the van's retrofit product won't work - I'm built for separate motors and sensors, not an all-in-one solution. My G3x is already programmed to show flap position using resistance in the same way as my fuel gauges if I install a POS-12, according to SteinAir.POS-12 measures resistance, and the avionics control is translating the numerical value into a proxy representation in degrees to display on a panel. You may need to understand this issue in more detail before trying to swap parts. Good luck. It’s similar to the fuel level being translated to gals for the display.

My issue isn't with how the POS functions or how to read it. My issue is that the Flap motor piston moves 5 inches. The POS sensor moves 1.2 inches. How do you measure where something is along a 5 inch path using a device with a 1.2 inch travel?

I believe the position sensor gets mounted on the flap arm, not on the flap motor. The flap arm moves in an arc and depending on how far out from the center you place it, it will move less than 5”. That said, the retrofit motor contains 5 wires: 2 for power/ground, and the other 3 for position (hi, low, posn). This should be the same as the combination Ray Allen sensor and old style flap motor. I’m not sure why it wouldn’t work the same way with your panel.

I have 6 wires from the Stein harness. 3 for the motor, 3 for the position sensor. Maybe one is ground in both cases, but someone at Stein said my harness is not compatible. Given that the power wire for the motor only flows when I hit the switch, power isn't in common between the circuits.I believe the position sensor gets mounted on the flap arm, not on the flap motor. The flap arm moves in an arc and depending on how far out from the center you place it, it will move less than 5”. That said, the retrofit motor contains 5 wires: 2 for power/ground, and the other 3 for position (hi, low, posn). This should be the same as the combination Ray Allen sensor and old style flap motor. I’m not sure why it wouldn’t work the same way with your panel.

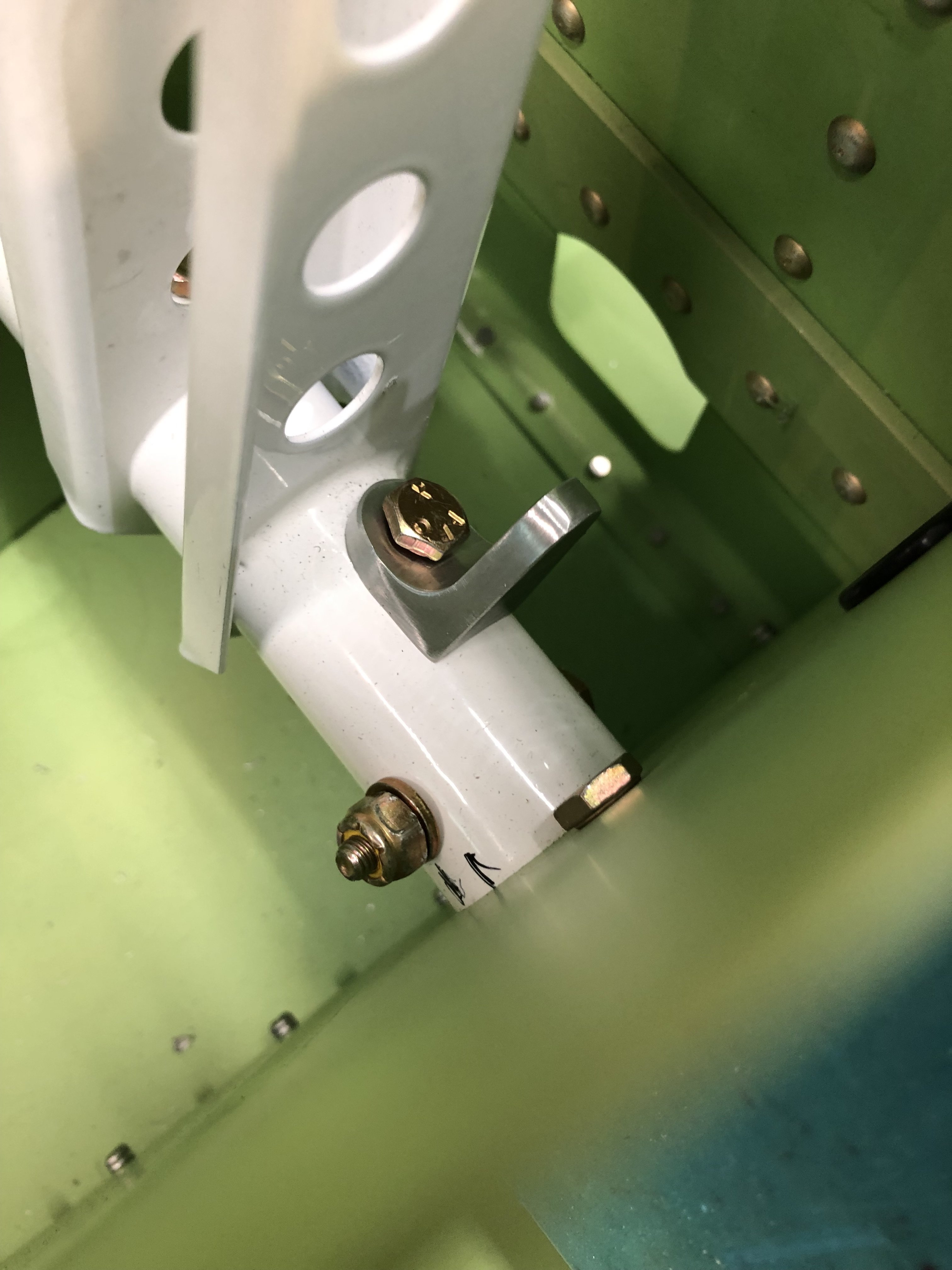

Thanks! Image saved for reference.This is how I mounted mine.

Richard Connell

Well Known Member

A little bit of high school trig and ratios to get the size of the small horn and you’re good to go. Disclaimer ignore hardware this was just trial fit

Wouldn’t you just wire the 3 in the stein harness for position to the 3 in the actuator which send out position? its exactly the same thing isn’t it? Adding the POS 12 is just duplicating what’s internal to the retrofit actuator?I have 6 wires from the Stein harness. 3 for the motor, 3 for the position sensor. Maybe one is ground in both cases, but someone at Stein said my harness is not compatible. Given that the power wire for the motor only flows when I hit the switch, power isn't in common between the circuits.