For the hive mind.

My friend purchased an almost-completed RV-14A a couple of years ago and finished it up and now has 80 hours on it.

During the first flight, and every subsequent flight, the G3X + Aithre 3.0 indicated high CO levels (50+). The exhaust system was pressurized with a vacuum cleaner outlet and soapy water sprayed everywhere. As expected, all of the exhaust ball/slip joints were leaking, but nowhere else.

A bit of HVAC "200MPH" tape was applied to the gaps between the aft edge of the top and bottom cowl aft edge and fuselage, and the CO levels decreased to ~50ppm in climb and 10ppm in cruise.

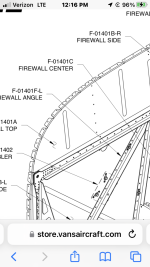

We've since inspected the firewall, and all penetration points, and found no air gaps or light leaks. We did change the cowling-to-fuselage attachment scheme from hinges to a continuous underlapping flange and screw affair (read: no gaps).

We're still chasing non-0 CO levels (~30 on climb out, 6ppm in cruise) . The remaining points that need some sealing are the bottom left & right corners of the cowl/fuselage.

We're going to take a handheld CO detector with us on the next flight to double check the Aithre.

Anyone else have suggestions?

My friend purchased an almost-completed RV-14A a couple of years ago and finished it up and now has 80 hours on it.

During the first flight, and every subsequent flight, the G3X + Aithre 3.0 indicated high CO levels (50+). The exhaust system was pressurized with a vacuum cleaner outlet and soapy water sprayed everywhere. As expected, all of the exhaust ball/slip joints were leaking, but nowhere else.

A bit of HVAC "200MPH" tape was applied to the gaps between the aft edge of the top and bottom cowl aft edge and fuselage, and the CO levels decreased to ~50ppm in climb and 10ppm in cruise.

We've since inspected the firewall, and all penetration points, and found no air gaps or light leaks. We did change the cowling-to-fuselage attachment scheme from hinges to a continuous underlapping flange and screw affair (read: no gaps).

We're still chasing non-0 CO levels (~30 on climb out, 6ppm in cruise) . The remaining points that need some sealing are the bottom left & right corners of the cowl/fuselage.

We're going to take a handheld CO detector with us on the next flight to double check the Aithre.

Anyone else have suggestions?