mountainride

Well Known Member

I have had my airplane wrapped for 4 years and for the most part it has held up well and been perfect! Exception is top of the cowling which would bubble after shutdown. I am rewrapping my top cowl today and found the culprit in the pinholes in the factory gelcoat. I had wrapped the fiberglass just as it came from vans besides cleaning really well.

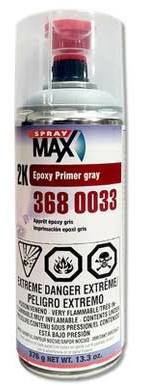

What is the best way to fill these pin holes without changing the contour or having a bunch of sanding? I am assuming I need to spray to get an even coat of whatever product I decide to use. Is there a rattlecan product that will fill these voids? Thanks for any advice.

What is the best way to fill these pin holes without changing the contour or having a bunch of sanding? I am assuming I need to spray to get an even coat of whatever product I decide to use. Is there a rattlecan product that will fill these voids? Thanks for any advice.