Any tip on for bending the longerons, is the flat part of the angle, the top,the other side the outside

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bending the Longerons

- Thread starter Danflyboyman

- Start date

D-Dubya

Well Known Member

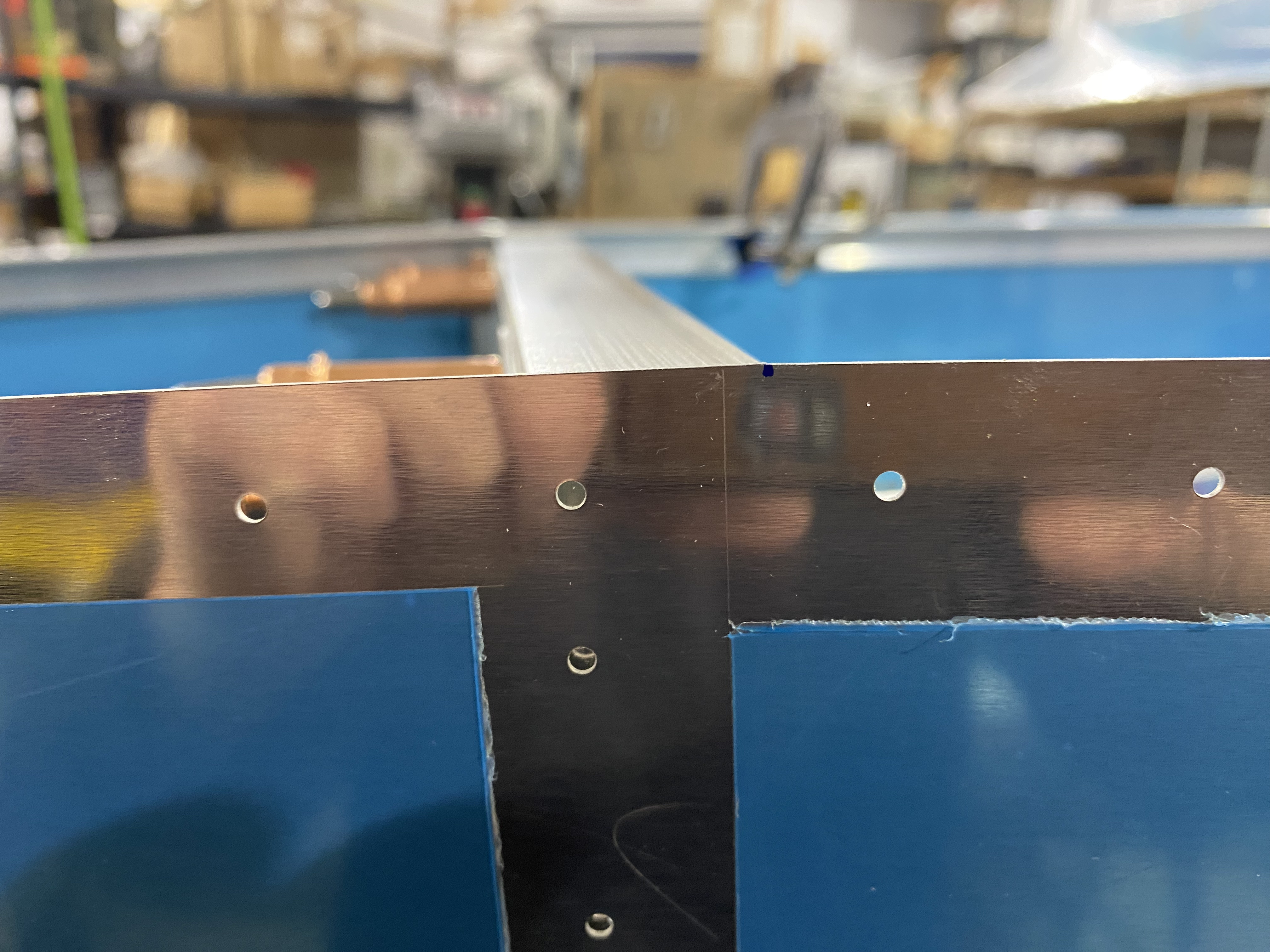

If I understand your question, yes the "flat" part will be the top, the curved part will be the side. You didn't state which RV you're working on, so this is only general information.

Go slowly and don't try to do too much with each hit. Following what others had done, I used a shot-filled dead-blow hammer, but there's probably any number of ways to do it. There was a learning curve to it, but I had another person help to pull the bend into the angle from behind me while I was coaxing it (beating) with the hammer. A vice securely mounted to a workbench in front of me was used to hold the angle in place, and aluminum angle pieces were used in the vice to prevent marring from the steel jaws. And whatever you do, don't forget that one side is a mirror of the other. Ideally, when you're done, you should be able to lay the two top surfaces back to back and there should be no gap between the two (where appropriate) and the curves should mirror each other. I think Van's said the tolerance should be within 1/16" of the template and each other.

Go slowly and don't try to do too much with each hit. Following what others had done, I used a shot-filled dead-blow hammer, but there's probably any number of ways to do it. There was a learning curve to it, but I had another person help to pull the bend into the angle from behind me while I was coaxing it (beating) with the hammer. A vice securely mounted to a workbench in front of me was used to hold the angle in place, and aluminum angle pieces were used in the vice to prevent marring from the steel jaws. And whatever you do, don't forget that one side is a mirror of the other. Ideally, when you're done, you should be able to lay the two top surfaces back to back and there should be no gap between the two (where appropriate) and the curves should mirror each other. I think Van's said the tolerance should be within 1/16" of the template and each other.

AND, It's not nearly as difficult as it sounds. Just take your time. When I did my first RV-6 back in 1989, I was surprised at how easy it was.If I understand your question, yes the "flat" part will be the top, the curved part will be the side. You didn't state which RV you're working on, so this is only general information.

Go slowly and don't try to do too much with each hit. Following what others had done, I used a shot-filled dead-blow hammer, but there's probably any number of ways to do it. There was a learning curve to it, but I had another person help to pull the bend into the angle from behind me while I was coaxing it (beating) with the hammer. A vice securely mounted to a workbench in front of me was used to hold the angle in place, and aluminum angle pieces were used in the vice to prevent marring from the steel jaws. And whatever you do, don't forget that one side is a mirror of the other. Ideally, when you're done, you should be able to lay the two top surfaces back to back and there should be no gap between the two (where appropriate) and the curves should mirror each other. I think Van's said the tolerance should be within 1/16" of the template and each other.

Dr_Dave_MT

Well Known Member

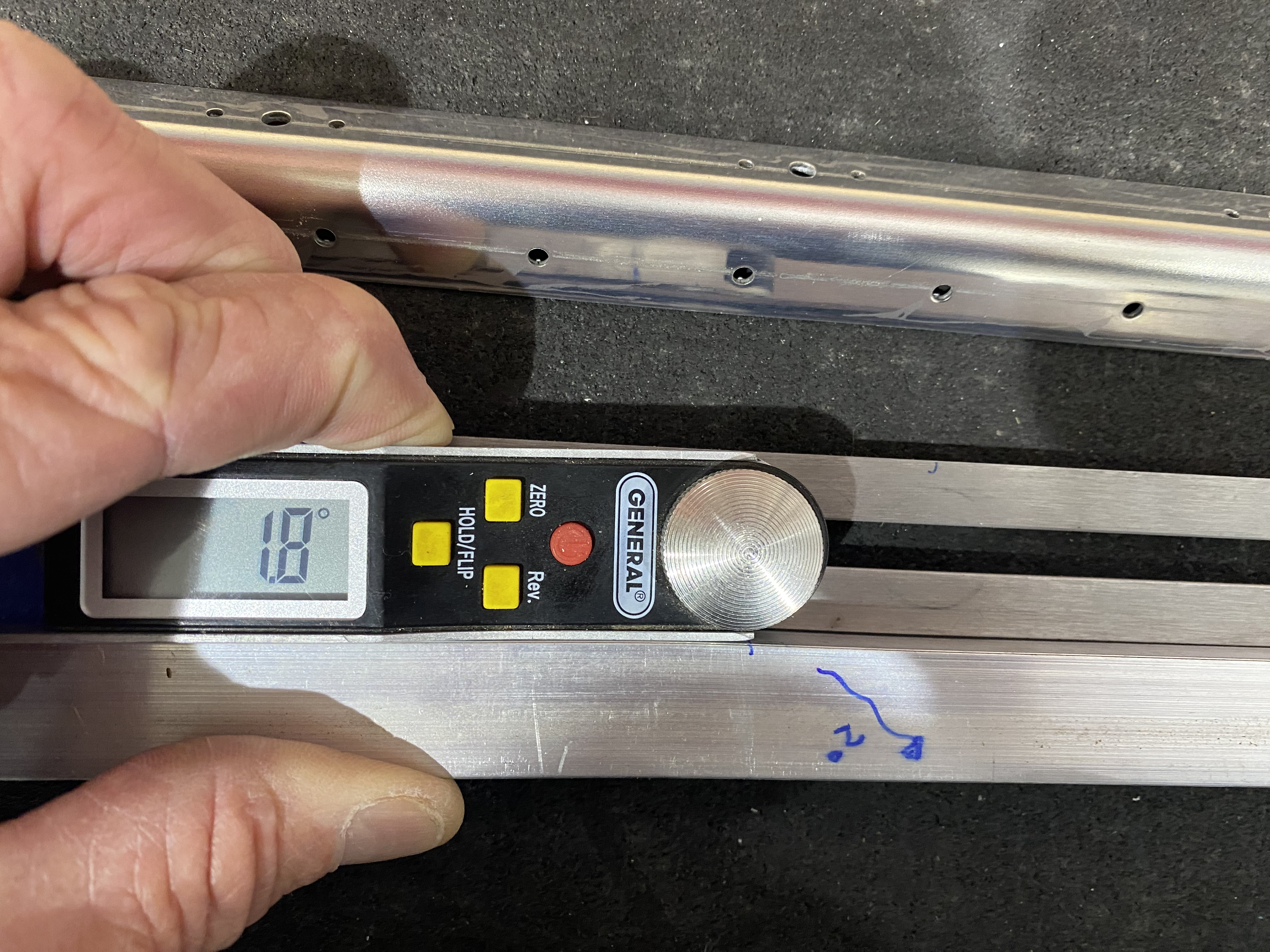

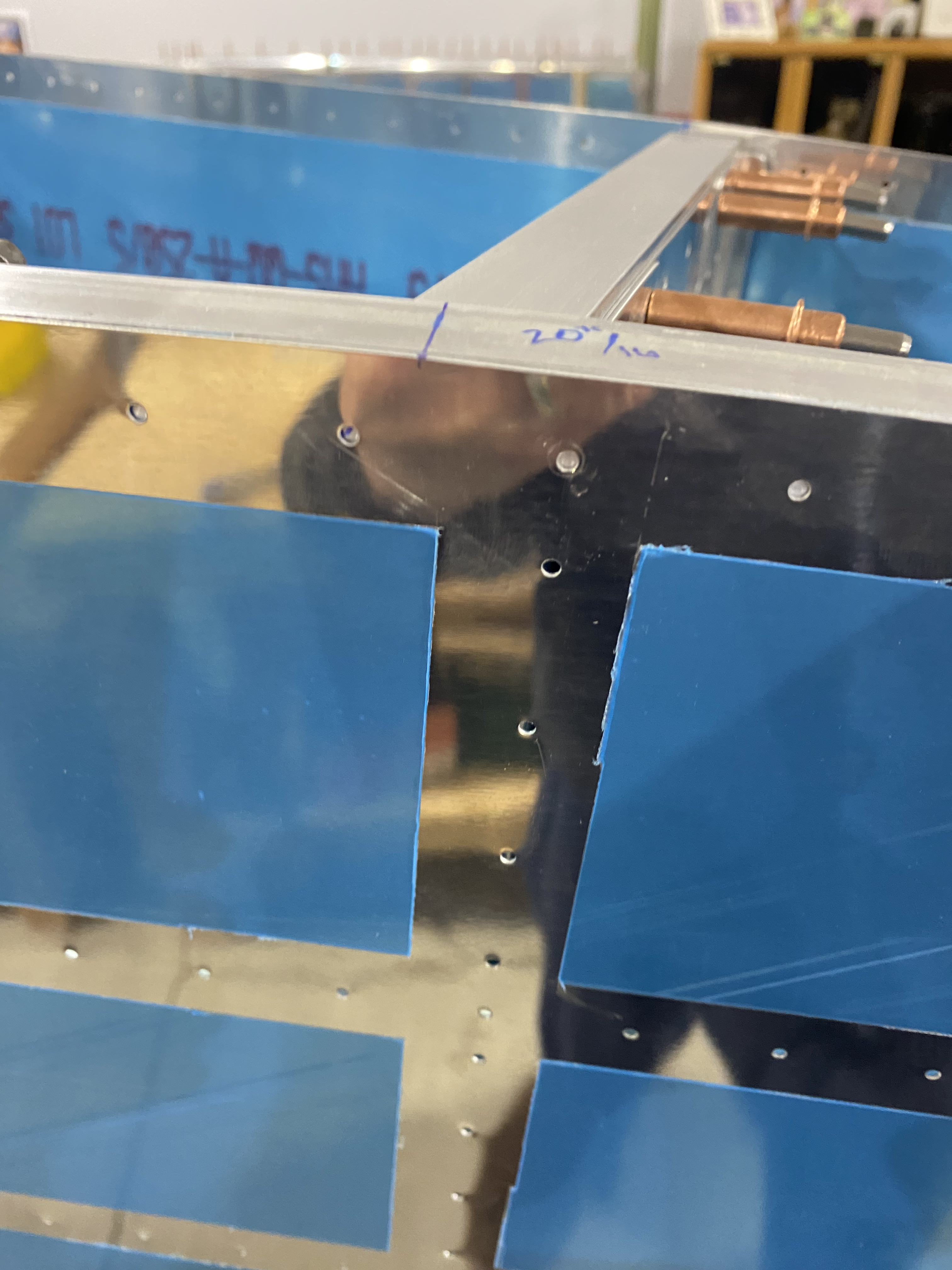

I agree with Mel, relax, and take your time. Mine is an RV-10. I used some items to hold the slight pre-load on the longeron at the far tip. Large rubber mallet with nice hits very close to the vise. Hold the longeron in pre-load with one hand, but wear gloves as the "twang" will hurt. I used my digital angle tool to match the skin angle.(about 1.8 degrees)

Last edited:

I’ve said it before and I’ll say it again… If you follow the instructions exactly, it really isn’t very difficult. I experienced the same trepidations that most builders feel as this section of the plans looms closer. But I spent some time carefully studying the plans, until I really understood what was happening. Then I went for it. Non event really. Took a couple of hours. You probably have a couple of extra pieces on the 10, but the concept is still the same. Gave me a confidence boost, and made tackling the other ‘challenging’ tasks easier.

Just my opinion. No doubt others feel differently.

Cheers, DaveH

Just my opinion. No doubt others feel differently.

Cheers, DaveH

I used the dies, and also bought a shorter piece of similar dimension angle from the local hardware store to practice on. Made 1" marks and shifted the longeron 1" between bends. Easy to overbend. Use the armrest as a guide. Similar to sealing the tanks in that it isn't as hard as it seems (either that or mine came out terrible and I'm just to dumb to know it!)

I’ve said it before and I’ll say it again… If you follow the instructions exactly, it really isn’t very difficult.

Cheers, DaveH

I've not gotten to this point in the build yet. BUT, the sentiment Dave expresses is true: things are not as hard as what is often opined on these pages. I have been paralized by fear at times only to find out the effort was not what I had read.

Give it a whirl. That's our plan when we get here.

Best of luck!

Mike

$49.00