Hi!

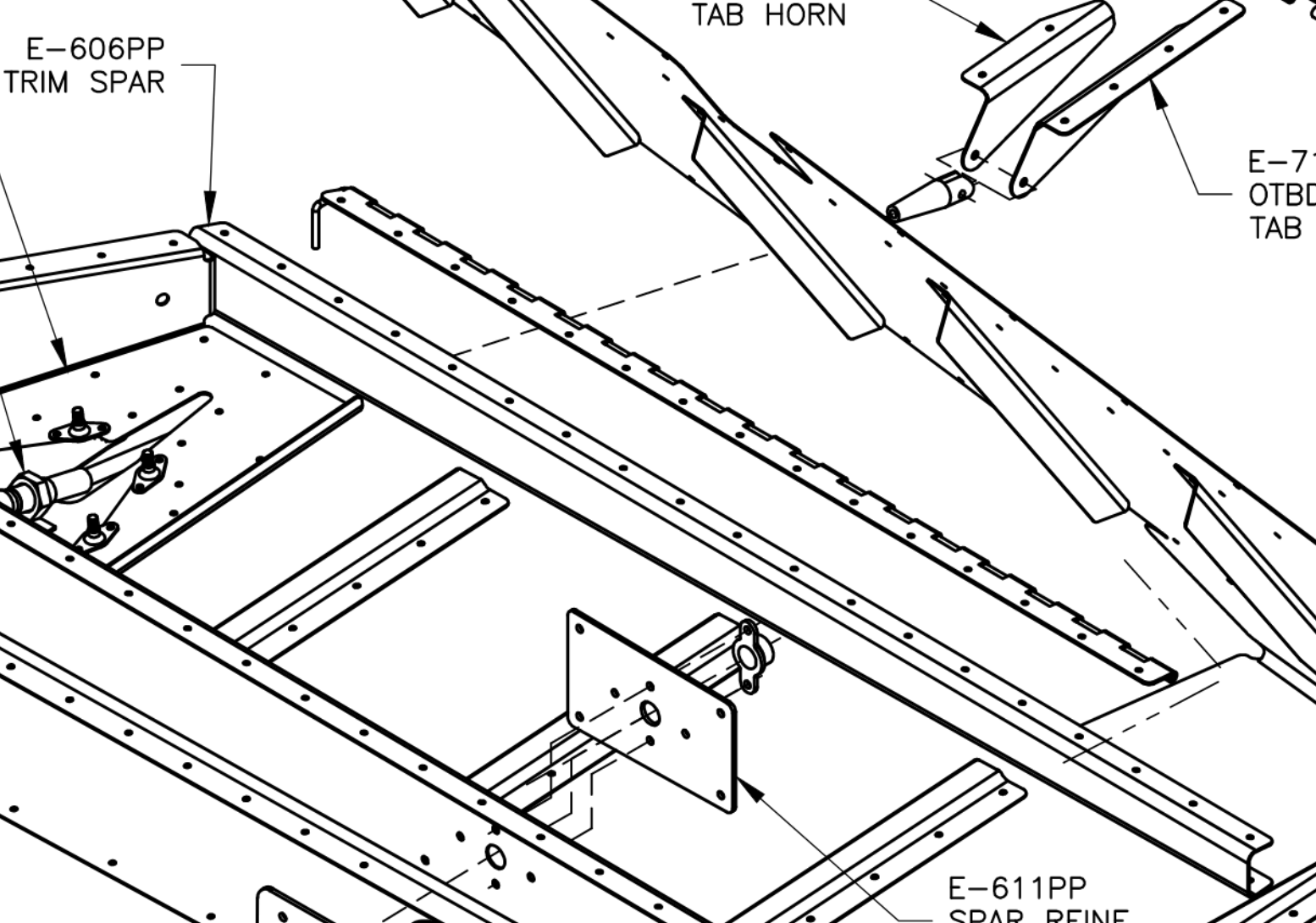

I screwed up and dimpled the bottom flange on E-606PP along with the skin. Of course, that's an issue since there's a hinge that goes in between the two. Is there any way to fix this, or do I need to order a new E-606PP?

Maybe the hinge could rivet to the underside of the flange, instead of in between the skin E-606PP? This would make the trim tab not align though, right?

Maybe I could dimple the hinge instead of machine countersinking it, though I know the hinge material is too thick to normally dimple.

Any ideas? Or should I drill out the 22 rivets and replace it - hopefully not damaging the skin in the process?

I screwed up and dimpled the bottom flange on E-606PP along with the skin. Of course, that's an issue since there's a hinge that goes in between the two. Is there any way to fix this, or do I need to order a new E-606PP?

Maybe the hinge could rivet to the underside of the flange, instead of in between the skin E-606PP? This would make the trim tab not align though, right?

Maybe I could dimple the hinge instead of machine countersinking it, though I know the hinge material is too thick to normally dimple.

Any ideas? Or should I drill out the 22 rivets and replace it - hopefully not damaging the skin in the process?