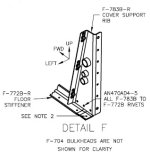

I'm riveting a few fuselage skeleton areas before final assembly of the forward fuselage on my RV7. It's going fine so far except for a couple of nasty rivets which join the inboard cover support rib (F-783B) to the inboard floor stiffener (F-772B - excerpt from DWG 23 is below). The aft-most rivet is nestled close to the center section flange, and there's also a bolt head nearby to make things even more difficult. Does anyone remember how they set this rivet? To drive it I think would need the double-offset rivet set (a.k.a. rivet mangler), and it won't be possible to get it totally perpendicular. My pneumatic squeezer certainly won't fit in there. Even setting a pulled rivet looks hard. Any help much appreciated! Thank you.

Van's Air Force

Don't miss anything! Register now for full access to the definitive RV support community.

Tough rivet - help please!

- Thread starter AndyWW

- Start date