All,

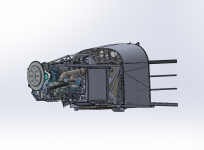

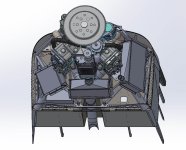

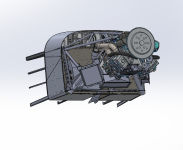

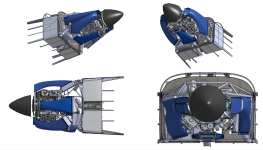

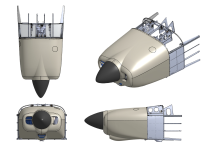

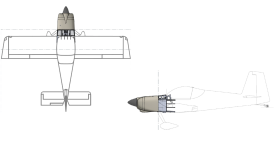

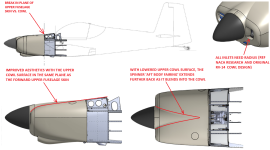

Here are some more CADs on the engine installation. These show more detail on what will be the final locations of the heat exchangers and sundry other things.

The engine and component layout phase is taking longer than we expected - but, this is largely because our goal is a complete package ready to present to other RV builders, not just a Frankenstein-ed test bed that isn't ready for mass uptake. If we are successful in this (and, I believe we will be) - there will be very little development work left to do between the package (engine prop, firewall forward stuff) we're putting on my RV14 and what will be later offered to the general RV14 community of builders.

Here are some of the components we are working on and a few thoughts on each:

Cowling: DH is working with a cowling manufacturer on a carbon fiber model. The shape will be very similar to the stock cowl, but distinct enough to telegraph there is something different under the hood. There will be some weight savings as well.

Prop: DH is speaking with a number of prop manufacturers. We have a few choices right now on props that will work, but are looking to narrow this down to one or two 'preferred' props. There is potential to save weight in this area as well (both in the prop and the spinner components).

Panel: We have been working directly with Aerotronics on the panel. Jason Smith (Aertronics) has been exceptionally helpful. Synergy and I have worked with him in the past and his technical knowledge combined with his understanding of pilot needs (he flys, too) is invaluable. The DH engine being different in many ways from the lycoming (no mags, no plugs, turbocharged, etc., etc.) has a lot of downstream impacts on the architecture and functionality of the panel. Jason has helped us sort this all out. We only just finalized the design and I will soon publish the layout for all to see. Its a full IFR Garmin set-up. I've been flying extensively (about 1000 hours) behind a similarly designed and equipped panel (albiet, for a Lycoming), and from a pilots/flying perspective its great.

With all this said - I have to say we will not be flying before OSH 2024. Bummer. It does, however, look like we will have the engine package installed to the fuselage and on display at Air Venture 2024 for everyone to see. We should have static test runs completed by then as well.

Once Air Venture 2024 has ended, the engine/fuse will be shipped to SynergyAir in Eugene for final assembly and test flights. Realisticly, this means the first flight data will probably not be out until October. We will, nonetheless, keep posting on the progress as we move forward.

One last note - Delta Hawk and Piper Aircraft Company just reached an agreement to "begin development of a Supplemental Type Certificate (STC) for installation of DeltaHawk’s engine in Piper’s legendary PA-44 Seminole twin in both new and retrofit aircraft". I know there are folks who question DH's commitment and/or capabilities to fullfill the promises of this engine's development. Its certainly been a long time in process. But, there are many signs to indicate they are indeed committed and it appears many end users are excited about the capabilities of the engine. I can attest that they are fully engaged on working with the experimental community.

And, one last addendum: Here's a YouTube link to an Aviation Consumer piece on DeltaHawk at Sun'N' Fun. If you look fast at the 5:30 mark you'll see our RV14 project.

Here are some more CADs on the engine installation. These show more detail on what will be the final locations of the heat exchangers and sundry other things.

The engine and component layout phase is taking longer than we expected - but, this is largely because our goal is a complete package ready to present to other RV builders, not just a Frankenstein-ed test bed that isn't ready for mass uptake. If we are successful in this (and, I believe we will be) - there will be very little development work left to do between the package (engine prop, firewall forward stuff) we're putting on my RV14 and what will be later offered to the general RV14 community of builders.

Here are some of the components we are working on and a few thoughts on each:

Cowling: DH is working with a cowling manufacturer on a carbon fiber model. The shape will be very similar to the stock cowl, but distinct enough to telegraph there is something different under the hood. There will be some weight savings as well.

Prop: DH is speaking with a number of prop manufacturers. We have a few choices right now on props that will work, but are looking to narrow this down to one or two 'preferred' props. There is potential to save weight in this area as well (both in the prop and the spinner components).

Panel: We have been working directly with Aerotronics on the panel. Jason Smith (Aertronics) has been exceptionally helpful. Synergy and I have worked with him in the past and his technical knowledge combined with his understanding of pilot needs (he flys, too) is invaluable. The DH engine being different in many ways from the lycoming (no mags, no plugs, turbocharged, etc., etc.) has a lot of downstream impacts on the architecture and functionality of the panel. Jason has helped us sort this all out. We only just finalized the design and I will soon publish the layout for all to see. Its a full IFR Garmin set-up. I've been flying extensively (about 1000 hours) behind a similarly designed and equipped panel (albiet, for a Lycoming), and from a pilots/flying perspective its great.

With all this said - I have to say we will not be flying before OSH 2024. Bummer. It does, however, look like we will have the engine package installed to the fuselage and on display at Air Venture 2024 for everyone to see. We should have static test runs completed by then as well.

Once Air Venture 2024 has ended, the engine/fuse will be shipped to SynergyAir in Eugene for final assembly and test flights. Realisticly, this means the first flight data will probably not be out until October. We will, nonetheless, keep posting on the progress as we move forward.

One last note - Delta Hawk and Piper Aircraft Company just reached an agreement to "begin development of a Supplemental Type Certificate (STC) for installation of DeltaHawk’s engine in Piper’s legendary PA-44 Seminole twin in both new and retrofit aircraft". I know there are folks who question DH's commitment and/or capabilities to fullfill the promises of this engine's development. Its certainly been a long time in process. But, there are many signs to indicate they are indeed committed and it appears many end users are excited about the capabilities of the engine. I can attest that they are fully engaged on working with the experimental community.

And, one last addendum: Here's a YouTube link to an Aviation Consumer piece on DeltaHawk at Sun'N' Fun. If you look fast at the 5:30 mark you'll see our RV14 project.

Attachments

Last edited: