I’m still a mostly off comm, deep in study mode. Light at the end of the tunnel - still just a tiny pinhole of light, but growing. In the meantime, here’s a super rare ‘Super Bowl’ edition of the VAF News. Now, back to the study closet for me…

v/r,dr

VAF POSTS & RV NEWS THAT CAUGHT MY EYE.....dr:

--------------------------------------------

White exhaust valve on 390EXP119 …Jetmart

Here are mine with appropriate times on them. All pics are LOP after the first 25 hrs of initial break in. I have no idea why cyl 1 & 2 formed the yellow ring at 94 hrs. Was told not to worry about it.

https://vansairforce.net/threads/white-exhaust-valve-on-390exp119.224395/#post-1747453

Newly Minted DAR …Paul Dye

Just a little less than a year ago, I dropped in to the Reno FSDO to pick up some Ops Lims for our eXenos, and was met by the three guys in the office that generally do E-AB inspections and issue AWC's. They were there to apologize that it took several months to get around to do our inspection, and that they had decided that they needed a DAR...and I was going to be it! “Slow forward” to today, when (ten months later) I received my DAR-T Letter of Authority and number!

It will take a few months to get through a couple of inspection with my FSDO inspector (sort of an OJT period), but when I have the hang of the paperwork process, I should be available for inspections as people need them. I feel very much like the new kid on the block compared to the experienced DAR's we have in this community (Mel, Vic, Tony, Scott....just to name a few), but hope to keep learning and helping folks turn their projects into airplanes in the years to come!

vansairforce.net

...Paul's listing added to 'The VAF List' at:

vansairforce.net

...Paul's listing added to 'The VAF List' at:

www.vansairforce.net

www.vansairforce.net

ES 85615-10 loose cover tube

The cover tube on my assembly was only hand tight. Have others seen this? Should I just add some thread locker and move on?

www.vansairforce.net

www.vansairforce.net

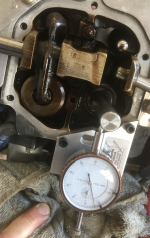

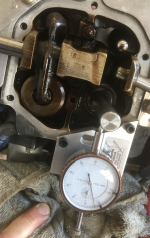

From the Rope Thread…Dan 57

Not sure spending your time on this is being worth it. First point is that the kit being sold by ACS fits the bill pretty good. Second is that given a few practice runs, one doesn't need to measure anything at all, but once the springs are removed will feel the fluidity of the valve stem movement, and then check the lateral play by finger feel... that will be enough to ensure no sticky valve.

As a side note, I've had several valves sticking over the years, on different airplanes with different engines, and one of the reasons I stopped using the Phillips 66 XC oil..

www.vansairforce.net

www.vansairforce.net

Question on drag (closing the tunnel)….Jetmart PIREP

I have a 14 with the non EXP engine and cowl and used the Vetterman exhaust. I modified the lower cowl to allow exhaust to exit but did not close up the exit space between the pipes. I installed the EXP tunnel cowl flap. I have found that the cowl flap is not that effective because of the larger exit area that I left open between the pipes. I have plenty of exit area with the cowl flap closed. If I were doing it again I would really have to consider just closing the tunnel area and not putting the cowl flap in or closing some additional cowl exit area. Currently I get about a 2 degree drop in oil temp with cowl flap closed versus open. CHT's are never an issue. I only use the cowl flap on landing in attempt to keep under cowl temps lower after landing. Also not sure I reduced much drag with the exit area being so large, certainly don't see any speed change with cowl open versus closed.

https://www.vansairforce.net/threads/question-on-drag-closing-the-tunnel.224423/#post-1747529

Trim Tab Data …

Steve and company, what do we think about the new deflection angle of the trim tab and the covered holes?

https://vansairforce.net/threads/ho...ease-the-p-factor-e-props.224259/post-1746327

Carb Heat Effectiveness and RPM Drop?

My 2ct...

The RPM drop will be heavily dependant upon which type of muff is installed. The one installed on my baby pictured below is certainly more a carb warmer, or alternate air. The RPM drop is insignificant at around 10-20. In view of this and the text below, the carb heat operation is only checked at every 50h inspection.

Beware, the observations as related below apply specifically to my airplane as equipped with said muff and the standard Van's FAB.

I've now flown my -6.9i for more than 1'500hrs and encountered light, and medium airframe icing. A single encounter with what was probably severe icing had the engine sputter after a short while. Pulling the carb "heat" knob and the engine returned to normal ops immediately, so the cause was probably an iced clogged snout, and pulling that knob restored air supply to the carb/engine.

Other than that, I've never had any sign of carb ice during operations, so basically never use carb heat during flight or ground ops.

vansairforce.net

vansairforce.net

OFF TOPIC:

PS: Older issues of the ‘VAF News’ can be found at:

www.vansairforce.net

www.vansairforce.net

v/r,dr

VAF POSTS & RV NEWS THAT CAUGHT MY EYE.....dr:

--------------------------------------------

White exhaust valve on 390EXP119 …Jetmart

Here are mine with appropriate times on them. All pics are LOP after the first 25 hrs of initial break in. I have no idea why cyl 1 & 2 formed the yellow ring at 94 hrs. Was told not to worry about it.

https://vansairforce.net/threads/white-exhaust-valve-on-390exp119.224395/#post-1747453

Newly Minted DAR …Paul Dye

Just a little less than a year ago, I dropped in to the Reno FSDO to pick up some Ops Lims for our eXenos, and was met by the three guys in the office that generally do E-AB inspections and issue AWC's. They were there to apologize that it took several months to get around to do our inspection, and that they had decided that they needed a DAR...and I was going to be it! “Slow forward” to today, when (ten months later) I received my DAR-T Letter of Authority and number!

It will take a few months to get through a couple of inspection with my FSDO inspector (sort of an OJT period), but when I have the hang of the paperwork process, I should be available for inspections as people need them. I feel very much like the new kid on the block compared to the experienced DAR's we have in this community (Mel, Vic, Tony, Scott....just to name a few), but hope to keep learning and helping folks turn their projects into airplanes in the years to come!

Newly Minted DAR….

Just a little less than a year ago, I dropped in to the Reno FSDO to pick up some Ops Lims for our eXenos, and was met by the three guys in the office that generally do E-AB inspections and issue AWC's. They were there to apologize that it took several months to get around to do our inspection...

THE VAF LIST

The VAF List RV-related things you might want to browse over (a closed post that is sticky and maintained by dr). Link to this in 'Links' in the menu. v/r,dr Small biz that brings you this page: 360 Avionics www.360Avionics.com Aircraft Extras www.aircraftextras.com Aircraft Propeller Service...

ES 85615-10 loose cover tube

The cover tube on my assembly was only hand tight. Have others seen this? Should I just add some thread locker and move on?

ES 85615-10 loose cover tube

The cover tube on my assembly was only hand tight. Have others seen this? Should I just add some thread locker and move on?

From the Rope Thread…Dan 57

Not sure spending your time on this is being worth it. First point is that the kit being sold by ACS fits the bill pretty good. Second is that given a few practice runs, one doesn't need to measure anything at all, but once the springs are removed will feel the fluidity of the valve stem movement, and then check the lateral play by finger feel... that will be enough to ensure no sticky valve.

As a side note, I've had several valves sticking over the years, on different airplanes with different engines, and one of the reasons I stopped using the Phillips 66 XC oil..

Sticky valve on a Thunderbolt IO390

As an opposing data point my 390 thunderbolt oil does not get black and goes aboit 20 hours plus on a quart maybe more. My hours are a lot of cruise and joyride. I don’t do a lot of aggressive flying or much pattern work. Perhaps the use of the engine is a key factor.

Question on drag (closing the tunnel)….Jetmart PIREP

I have a 14 with the non EXP engine and cowl and used the Vetterman exhaust. I modified the lower cowl to allow exhaust to exit but did not close up the exit space between the pipes. I installed the EXP tunnel cowl flap. I have found that the cowl flap is not that effective because of the larger exit area that I left open between the pipes. I have plenty of exit area with the cowl flap closed. If I were doing it again I would really have to consider just closing the tunnel area and not putting the cowl flap in or closing some additional cowl exit area. Currently I get about a 2 degree drop in oil temp with cowl flap closed versus open. CHT's are never an issue. I only use the cowl flap on landing in attempt to keep under cowl temps lower after landing. Also not sure I reduced much drag with the exit area being so large, certainly don't see any speed change with cowl open versus closed.

https://www.vansairforce.net/threads/question-on-drag-closing-the-tunnel.224423/#post-1747529

Trim Tab Data …

Steve and company, what do we think about the new deflection angle of the trim tab and the covered holes?

https://vansairforce.net/threads/ho...ease-the-p-factor-e-props.224259/post-1746327

Carb Heat Effectiveness and RPM Drop?

My 2ct...

The RPM drop will be heavily dependant upon which type of muff is installed. The one installed on my baby pictured below is certainly more a carb warmer, or alternate air. The RPM drop is insignificant at around 10-20. In view of this and the text below, the carb heat operation is only checked at every 50h inspection.

Beware, the observations as related below apply specifically to my airplane as equipped with said muff and the standard Van's FAB.

I've now flown my -6.9i for more than 1'500hrs and encountered light, and medium airframe icing. A single encounter with what was probably severe icing had the engine sputter after a short while. Pulling the carb "heat" knob and the engine returned to normal ops immediately, so the cause was probably an iced clogged snout, and pulling that knob restored air supply to the carb/engine.

Other than that, I've never had any sign of carb ice during operations, so basically never use carb heat during flight or ground ops.

Carb Heat Effectiveness and RPM Drop?

On my RV-9A (O-320), there is no noticeable RPM drop when I apply carb heat. On the other hand, the one time I had carb ice in the air, flying in and out of cumulus clouds on a summer day at maybe 6,000 feet or so, carburetor heat cleared it up immediately. What's the body of evidence on RV...

OFF TOPIC:

PS: Older issues of the ‘VAF News’ can be found at:

Doug's Area ....The VAF News & my flying resume.

Pushed out every now and then.

Last edited: